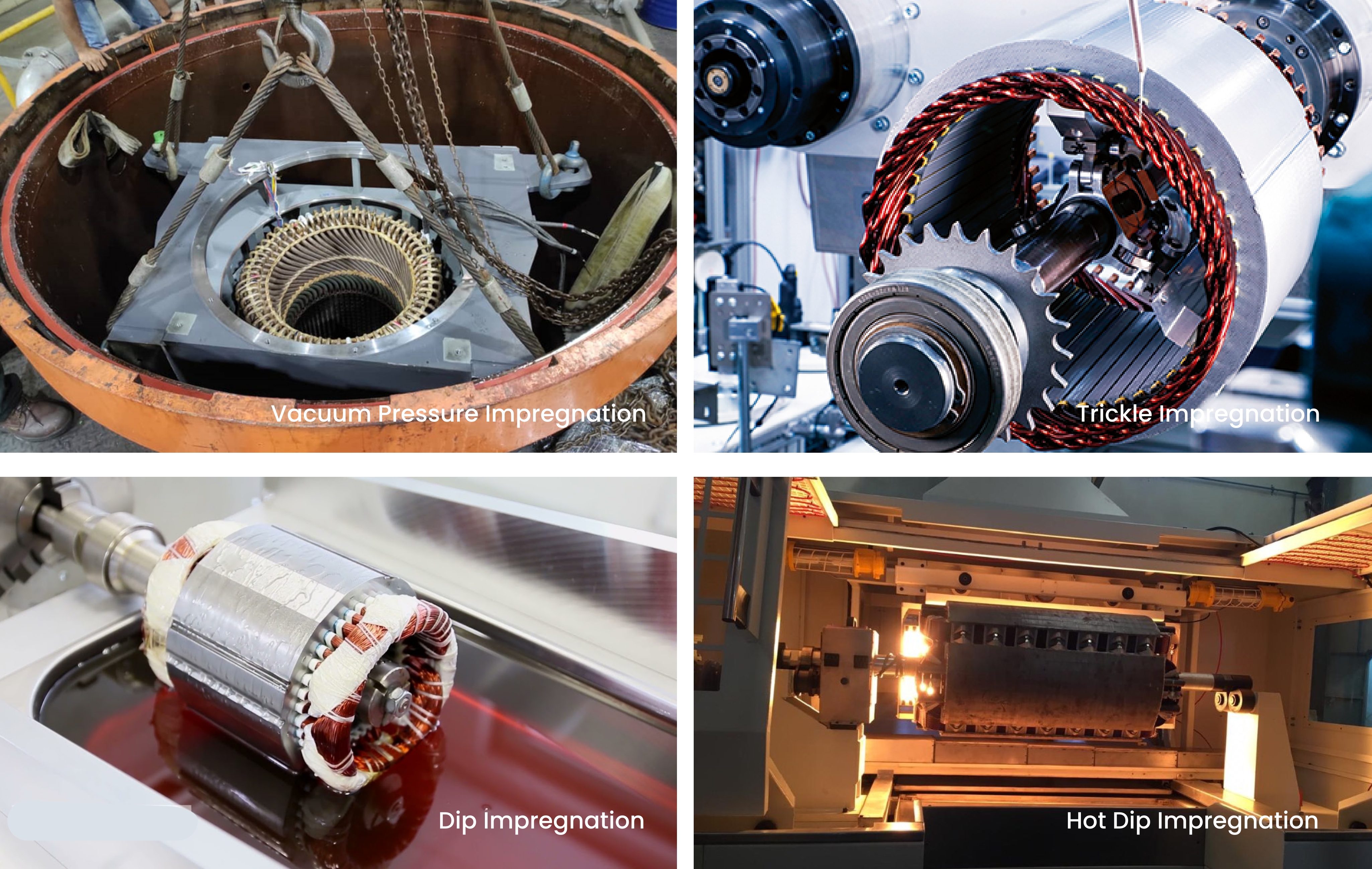

Impregnation Solutions

Impregnation in motors and coils is needed to enhance insulation, prevent moisture ingress, and improve thermal conductivity. We provide expert consultation on advanced impregnation techniques, including:

Vacuum Pressure Impregnation (VPI):

VPI is a process used to ensure complete saturation of insulating materials with resin under vacuum and pressure, enhancing durability and electrical performance.Refer Video 1

Trickle Impregnation

Trickle impregnation is a method where resin is applied in a controlled thin stream onto rotating, preheated components to achieve effective, localized saturation and improved insulating properties without excessive waste. Refer Video 2

Dip Impregnation

Dip impregnation involves submerging components in resin to achieve saturation Refer Video 3

Hot Dip Roll

Hot dip impregnation involves heating the resin to improve fluidity for better penetration into voids and cracks. Refer Video 4

Our tailored solutions ensure the reliability and longevity of your electrical components.

Photographs & Videos of the Processes